We are a certified prototype manufacturer for industry, energy and medical technology. The automotive industry and vehicle construction are especially among our customers.

The fast and high-quality production of prototypes made of aluminium using the sand casting process has become an indispensable part of today’s vehicle development. We implement your ideas in various aluminium alloys and also undertake subsequent thermal treatment. In addition to sand casting, we also produce plastic prototypes using the vacuum casting process. Our repertoire has several CNC milling centres for processing semi-finished products made of plastic, aluminium, copper, as well as steel and cast alloys. With a paperless and partially automated way of working, we are a reliable project partner for increasing your efficiency.

We manufacture your aluminium castings up to a size of 35 kg in our own production facility. We use different AL alloys according to your requirements.

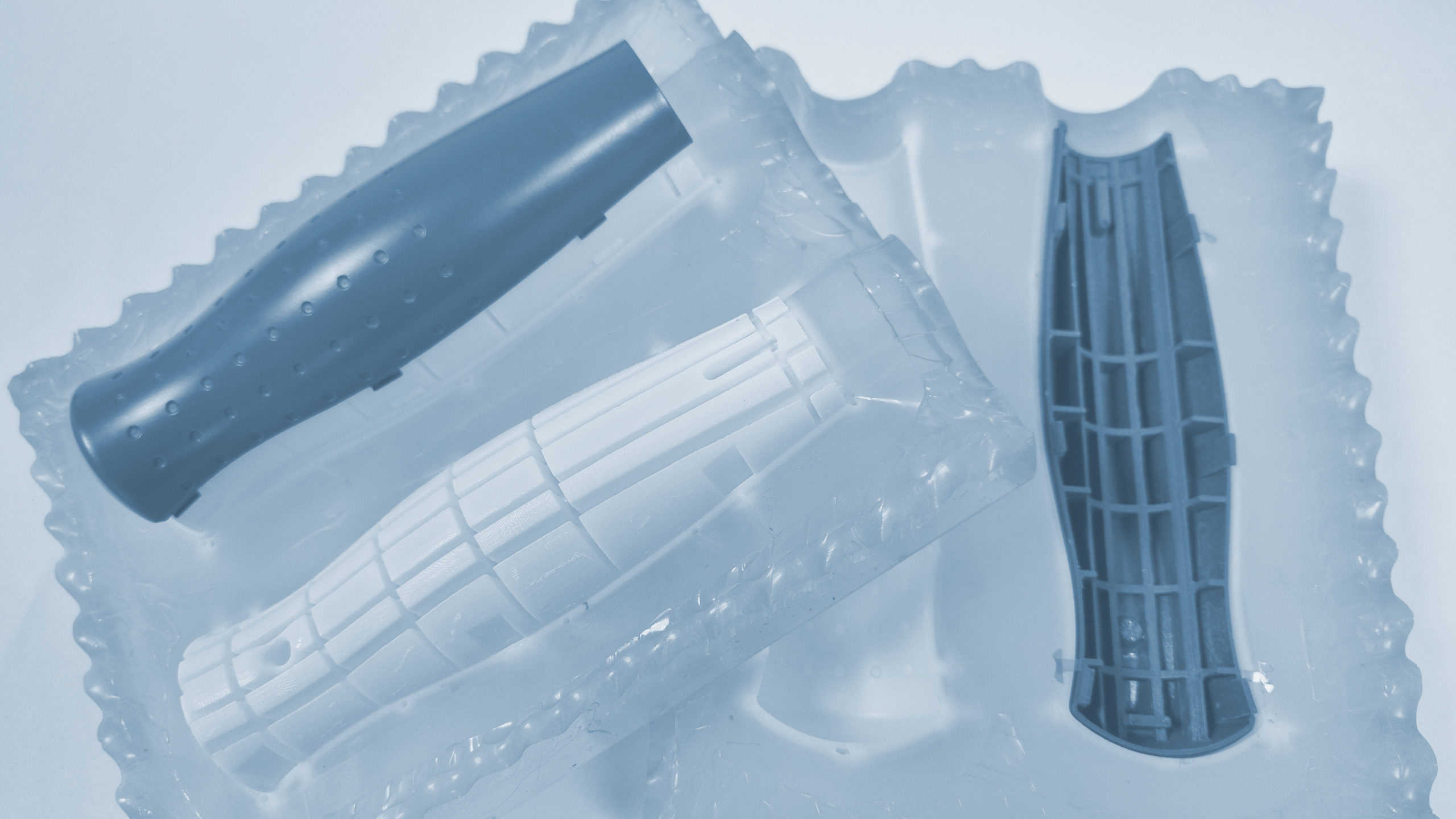

Using the vacuum casting process, we produce near-series plastic prototypes or small series made of plastic for you. We can also produce 2K components and overmoulded inserts.

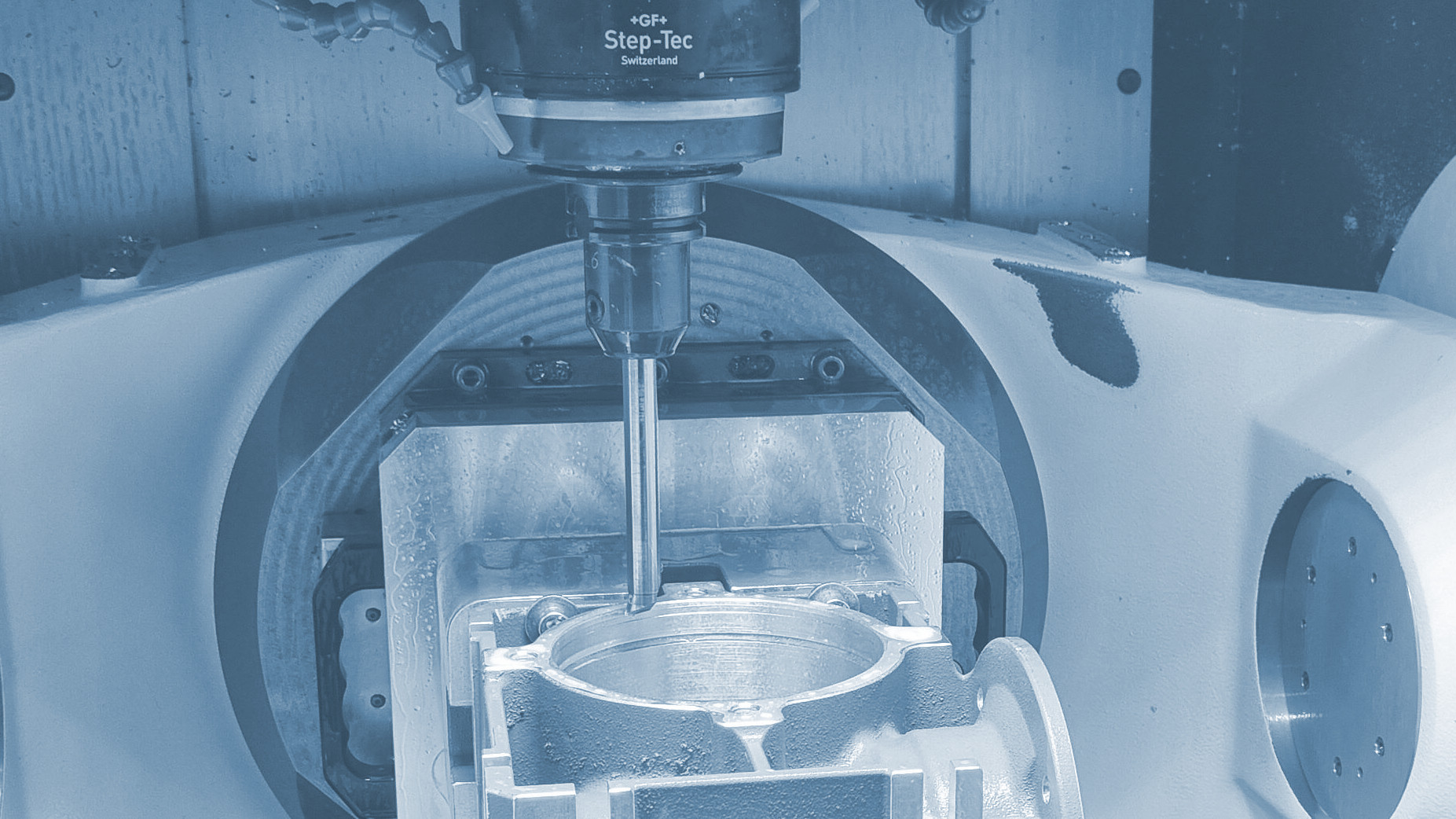

With our 5-axis CNC milling machines, we machine plastics and metals according to your wishes. We also realise rotationally symmetrical geometries by interpolation turning.

We reliably and efficiently manufacture your prototype to a high standard. To guarantee this, we permanently carry out quality controls in all areas by our qualified employees as well as by our in-house quality manager. Our products and processes comply with the ISO 9001 standard for quality management systems and the ISO 14001 standard for environmental management systems.

We are specialised in customised production solutions and individual prototype production. We are the right partner for you when it comes to realising your ideas. In doing so we, together with you and our partners, look for the ideal solution for your project. In order to realise this, we seek direct contact with you as our customer.

Contact us and we will find the perfect process to turn your ideas into a high-quality prototype quickly and cost-effectively!

Only those who continue to develop have a future. For us, this means investing in our company to remain fit for the future and to strengthen innovation. We place a special focus on the training of new skilled workers. We know that a functioning company is based on a strong team. As an employer, we take responsibility for our industry, for Saxony as a business location and, first and foremost, for the satisfaction of our employees.

Do you love unusual solutions and ideas as much as we do? Then join our team! You can find our current apprenticeships and job advertisements in our career portal.

We look forward to getting to know you!